Four Sisters in Ancient Rome includes reference to the making of textiles, in this month’s blog Dr Mary Harlow (University of Leicester) explains how the Romans made cloths in their own homes.

How did the Romans make their clothing? Today, when we are surrounded by clothes shops on the high street and on the internet, each of which might sell thousands of garments produced many miles away from the point of sale, it is hard to imagine the pre-industrial production of clothing and other textiles. Here, we will look briefly at the tools needed to make a Roman garment.

In Italy, most Romans wore garments made of wool or linen. Across the Roman world these were the predominant textiles – there was very little production of cotton and it was rarely used for clothing. As a large percentage of Roman cloth production was domestic, it is instructive to think of it from raw material to finished article and to see how many processes and people might have been involved. The writings of some Roman authors suggest that they were very aware of the best way to keep sheep, especially if they were bred for their wool (Columella 7.2.3-5; Pliny NH 8.73, 189-190; Mart. Ep. 14.155). Some sheep were even covered with leather jackets to protect their fine fleece (Pliny NH 8.189; Varro De Agri. 2.2.18-19), others were known for the colour and different quality of their wool. Once the fleece was off the sheep, it had to be prepared for spinning. This involved washing and combing in order to clean, separate and arrange the fibres so that the spun thread would be even and consistent. If the wool was to be dyed it might be done at this stage too, that is, before spinning. Flax also went through a similar series of processes, after it was harvested it would be dried, retted (a process that involved water to break down the fibres), and dried again. Next, it would be scutched (broken) and heckled to extract the workable inner fibre. This inner fibre would be spun to become linen thread.

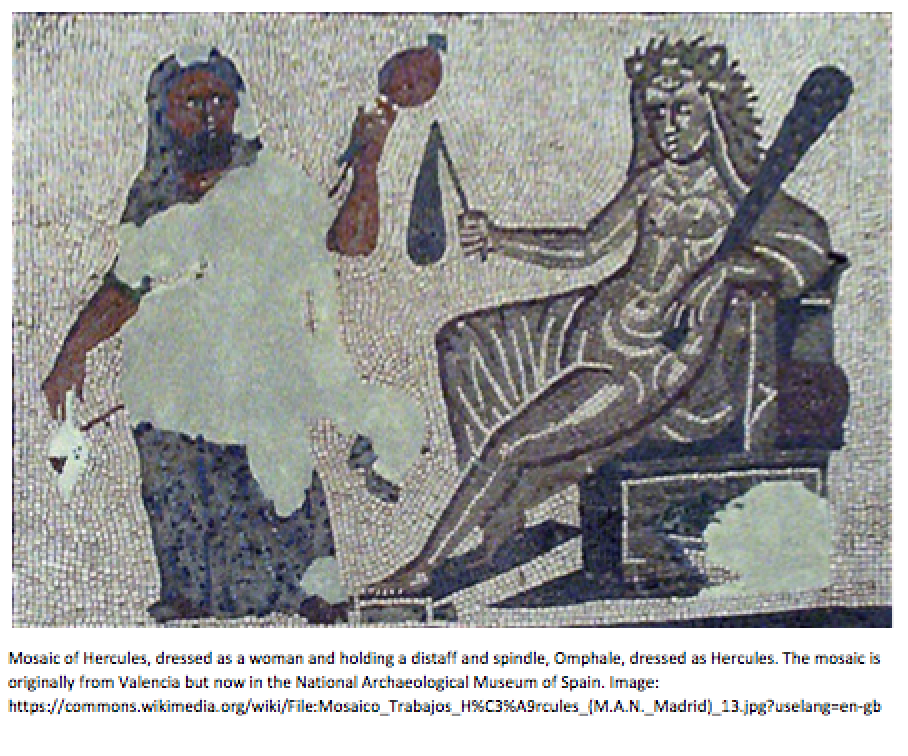

Spinning appears to be primarily a female activity and being able to ‘work wool’ was considered an essential skill for women. This skill became synonymous with the ideal of the virtuous woman and has become romanticised as part of the notion of the ideal matrona. In point of fact, preparing wool and spinning it was both hard work and very time consuming. Spinning was done by hand on a drop spindle. Many spindle whorls of different qualities have been found across the Roman world. Some are beautifully worked and decorated in stone or clay, while others, especially in Roman Britain, might be make of discarded pot sherds with a hole drilled through the centre. The functionality of spinning was not affected by the beauty of the spindle whorl but by its balance and weight. A simple, but not universal, rule would be that that lighter the spindle whorl, the thinner and finer the yarn spun. Most girls probably learnt to spin, and skilled spinners who could provide miles and miles of consistently high quality, standardised thread would have been in demand.

It was not the Roman tradition to weave spun thread into cloth which would then be cut and sewn into garments, rather they ‘wove-to-shape’ on the loom. This practice means that rather than look at a bolt of cloth and decide what you might like to make from it, a spinner and weaver might work together (indeed, might be the same person) from the beginning of the production process, choosing the best raw material to suit the garment they had in mind. The spinning could then be done to suit the type of garment, and the loom set up to produce the correct weave. A Roman weaver needed a number of skills, not least, mathematics, as arranging a loom set up is a very complex business. If it is done incorrectly, the final garment might end up wrongly sized or too loosely/tightly woven to be fit for purpose and that would mean a waste in valuable resources and time. Despite the fact that Augustus apparently insisted on his clothing being made by Livia and Julia (Suetonius, Aug. 71) it is more likely they supervised rather than spent all day with a spindle or setting up a loom.

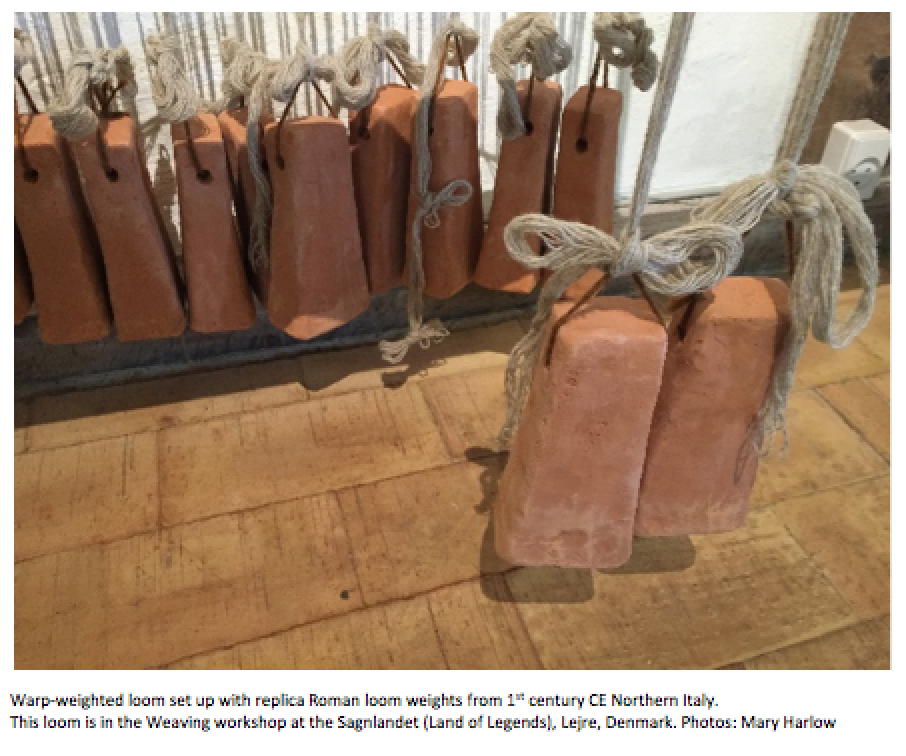

For most of the Roman period, in the Mediterranean, we can see evidence of two main types of loom: the warp-weighted loom and the two-beam loom. The warp-weighted loom had a long history before the Romans. It was an upright structure, often leant against a wall, in which the tension on the warp (vertical) threads was maintained by the use of weights. Despite the fact that it might look like rather simple technology, a warp weighted loom could be used to make complex textiles with patterns either interwoven, or created by different weave systems and contrasting spin tension/direction in the weft threads. A weaver would have to calculate the ideal number of treads in the warp and the optimum number to be attached to a weight to produce a good balanced weave which would retain its shape. Depending on the type of garment or textile to be produced, the spinner and the weaver would decide on the relative hardness of the spin in the warp, and the type of yarn to be used in the weft. The weft is the horizontal weave created by passing a thread under and over the warps. A weaver would stand to work a warp-weighted loom and beat the thread upwards, with the weave starting at the top of the loom and growing in a downwards direction. This can be very hard on the arms, shoulders and neck muscles! For very large garments, such as some tunics and certainly the toga, a loom of up to 4m might be required and more than one weaver would probably work on such a loom. Incidentally, to make an imperial toga might require up to 35km of thread, and, at the very least, a month of weaving time.

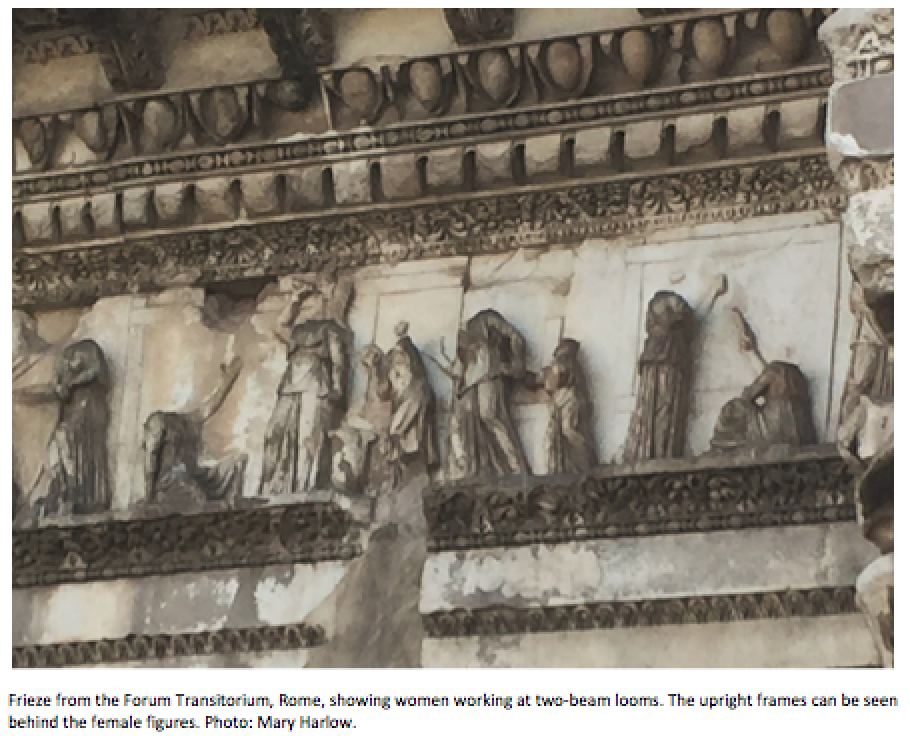

The Romans also knew of a two-beam loom, where the tension created by the loom weights was instead done by attaching warps to a beam. On this type of loom the weavers worked from the bottom up so it was possible to sit and work. The two-beam loom also allowed for the development of tapestry weaving, the technique by which most decoration was introduced into Roman clothing. Although we sometimes still read about ‘embroidered’ clothing, this was in fact a very rare technique in the Roman period, most patterns were in-woven during production on the loom.

Garments were taken off the loom and made ready for wear by sewing up the side seams, perhaps finished off by washing or by the attention of the fuller. Post-loom processes would have made the garment softer, have helped close up the weave, and perhaps enhanced the overall texture of the garment.

While the shapes of Roman clothing remained fairly basic, tunics were simply rectangular or T-shaped and cloaks/mantles also rectangular or semi-circular a great deal of difference could be created by the use of dyes, of patterns, of clavi, of different weave structures, and of course by the way the individual chose to wear them. As with fashion today, it was often not what you wore, but the way you wore it that created effect.

References

Gleba, M. and U. Mannering eds. 2012. Textiles and Textile Production in Europe from Prehistory to AD 400. Oxford.

Gleba, M. and J. Pásztókai-Szeöke eds.2013. Making Textiles in Pre-Roman and Roman Times: People, Places, Identities. Oxford.

Harlow, M. and M-L. Nosch eds. 2014. Greek and Roman Textiles and Dress. Oxford.