Dr Mahmood Shafiee, Reader in Mechanical Engineering at the School of Engineering and Digital Arts, has co-authored an article on ‘Unmanned Aerial Drones for Inspection of Offshore Wind Turbines: A Mission-Critical Failure Analysis‘ recently published in the journal Robotics.

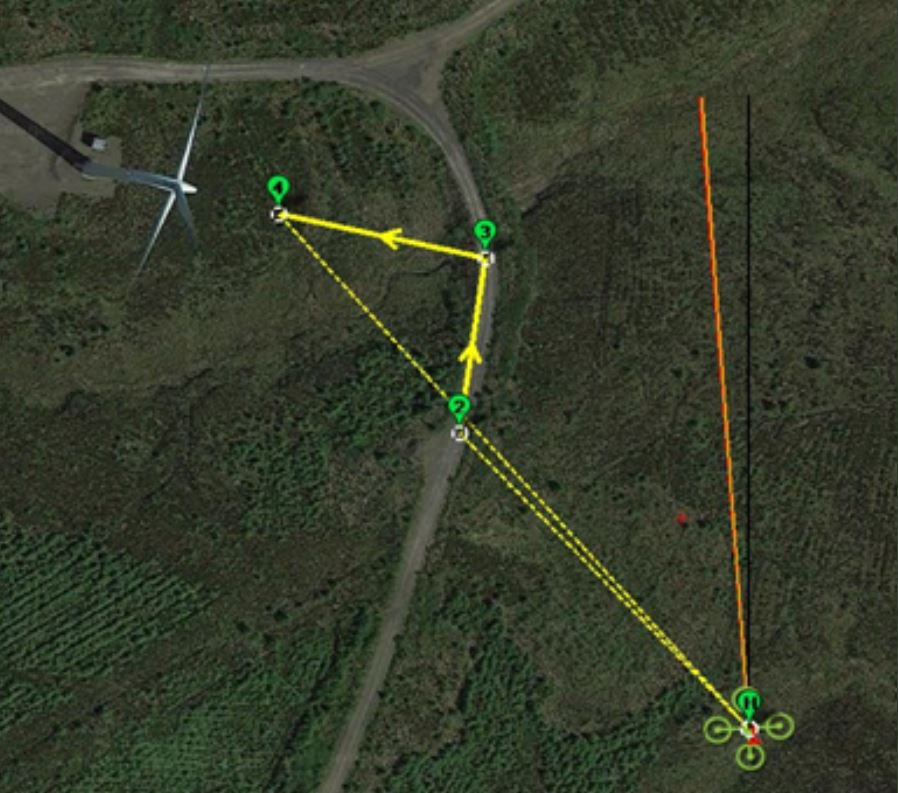

The article explores deploying an unmanned aerial drone in the Offshore Wind Industry for the first time. The drone can fly up to 400 feet and take images and videos of wind turbine nacelle, tower and rotor blades from different angles and directions.

The article, co-authored with Zeyu Zhou, Luyao Mei and Jackson Karama (Cranfield University), Fateme Dinmohammadi (Cranfield University and University College London), and David Flynn (Heriot-Watt University) is published in a special issue of Robotics on Advances in Robots for Hazardous Environments in the UK, and is part of a collaboration of more than 20 drone manufacturing and wind energy industries in the UK, Europe and Australia.

With increasing global investment in offshore wind energy and rapid deployment of wind power technologies in deep water hazardous environments, the in-service inspection of wind turbines and their related infrastructure plays an important role in the safe and efficient operation of wind farm fleets. The use of unmanned aerial vehicle (UAV) and remotely piloted aircraft (RPA)—commonly known as “drones”—for remote inspection of wind energy infrastructure has received a great deal of attention in recent years. Drones have significant potential to reduce not only the number of times that personnel will need to travel to and climb up the wind turbines, but also the amount of heavy lifting equipment required to carry out the dangerous inspection works. Drones can also shorten the duration of downtime needed to detect defects and collect diagnostic information from the entire wind farm. Despite all these potential benefits, the drone-based inspection technology in the offshore wind industry is still at an early stage of development and its reliability has yet to be proven. Any unforeseen failure of the drone system during its mission may cause an interruption in inspection operations, and thereby, significant reduction in the electricity generated by wind turbines. In this paper, we propose a semiquantitative reliability analysis framework to identify and evaluate the criticality of mission failures—at both system and component levels—in inspection drones, with the goal of lowering the operation and maintenance (O&M) costs as well as improving personnel safety in offshore wind farms. Our framework is built based upon two well-established failure analysis methodologies, namely, fault tree analysis (FTA) and failure mode and effects analysis (FMEA). It is then tested and verified on a drone prototype, which was developed in the laboratory for taking aerial photography and video of both onshore and offshore wind turbines. The most significant failure modes and underlying root causes within the drone system are identified, and the effects of the failures on the system’s operation are analysed. Finally, some innovative solutions are proposed on how to minimize the risks associated with mission failures in inspection drones.

The full paper is available to read here:

https://www.mdpi.com/2218-6581/10/1/26