By Professor John Todd, Emeritus Professor of Mass Spectroscopy

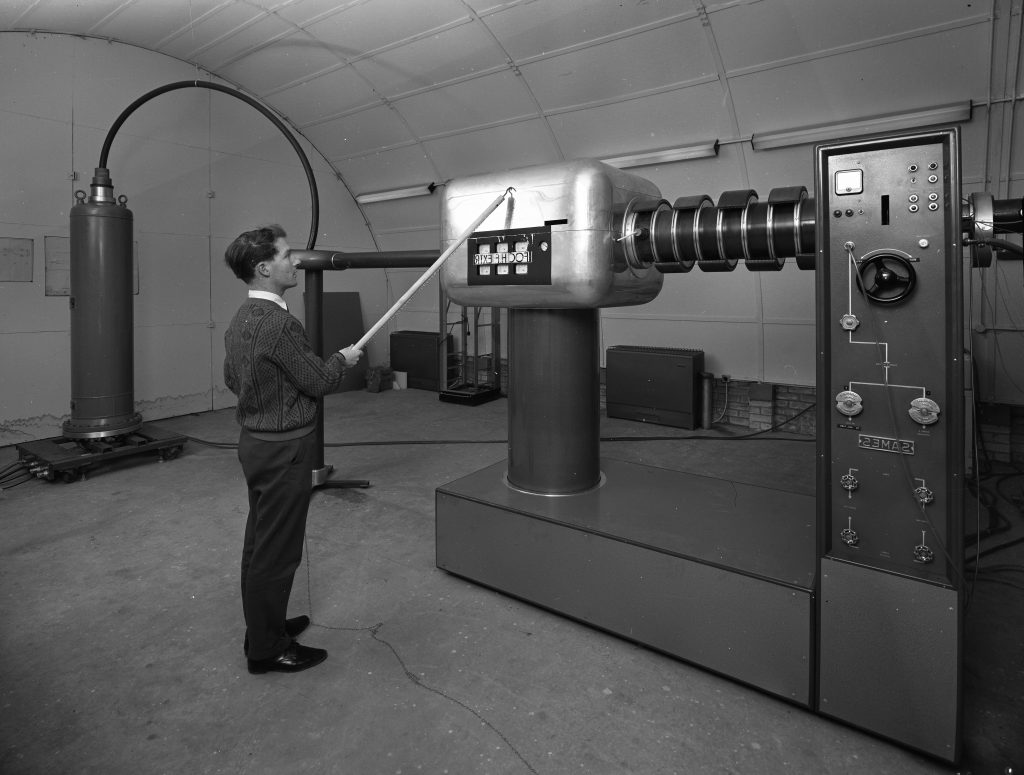

It was great to see the archive photo [in the April 2020 alumni e-newsletter], as I can tell you that this machine is (not surprisingly) none of your suggestions (a) to (c)! In fact the picture is of the 400,000 volt deuterium ion (‘deuteron’) accelerator that I used in some of my early research when I first arrived at Kent in 1965. Before I got here the machine had already been purchased by Professor Graham Martin (our first Professor of Chemistry who later became the first Dean of Natural Sciences and also succeeded Professor Guy Chilver as Deputy Vice-Chancellor), and was employed by his group for their radiochemistry and nuclear chemistry research. Initially the accelerator was accommodated in a Nissen hut at the back of Beverley Farm (as shown here), but once the new Chemical Laboratory was completed in 1967 it was moved to the concrete ‘tomb’ in the car park area at the back (now used by the Gulbenkian Theatre as costume store!).

The whole setup was pretty lethal when it was running, and involved electrically charging up the large aluminium container in the centre of the photo to the aforementioned 400,000 volts by means of the Van de Graaff generator on the left-hand side of the picture (which, incidentally is backwards way round, as revealed by close examination of the writing on the various labels). All the control console was in a separate room away from the machine, because when in use there was a significant radioactive background generated through the impact of the deuterons with a radioactive tritium-coated target which was contained in a housing, just off the right-hand side of the picture. Sample chemicals were then irradiated by the beam of high-energy neutrons released when the accelerated deuterons collided with the tritium atoms.

After a pre-determined irradiation time, the high voltage generator was switched off and one could ‘safely’ re-enter the chamber in order to retrieve the (now radioactive) samples for analysis. However it was important to remember that, even though the voltage was no longer being created by the generator, the aluminium chamber still carried a residual electrical charge, and so had to be ‘earthed’. This was done by touching the chamber with an earthing wire connected to a hook on the end of wooden broom handle(!), as demonstrated in the photo by one of our very early members of the technical staff, Bill Povey. Bill did not seem to come to any lasting harm doing this procedure, and I was delighted to meet up with him again at a talk I gave in Herne Bay last August (2019).