“The opportunity to work with academics and students from the University has given the company an early advantage in creating a sustainable business model with the potential of transforming the luxury yacht market.”

Tony Duke, Managing Director of The Duke Voyager’s Shipyard

Tony Duke has always enjoyed sailing. When his mother died in early 2020, he inherited her ashes, and a dream to sail them to his grandfather’s homeland in Africa on a yacht which will not pollute the planet. This led to the birth of his start-up, The Duke Voyager’s Shipyard, which aims to build a carbon neutral ocean sailing yacht that will make his dream a reality. He recognises that for the start-up to succeed, he needs to work with experts and that UK Universities are the place to find them. In 2022, he reached out to the University of Kent for support at one of our Net Zero Deep Dive training workshops.

The challenge

One of the challenges Tony and the Duke Voyager Shipyard face is finding a strong but environmentally friendly material with which to construct the yacht’s hull. Fibreglass has a carbon footprint of 1.7-2.5 tonnes C02-eq per tonne of fibre – approximately five times as much as natural fibres. There’s also the small matter of how to sustainably fuel the manufacturing process and minimise transportation of materials.

When Tony heard about the Net Zero Deep Dive workshops funded by the Government’s Community Renewal Fund and led by University of Kent academics in partnership with the Kent Invicta Chamber of Commerce to help businesses reach their net zero objectives, he saw an opportunity to access funding and expertise to overcome some of these challenges.

The approach

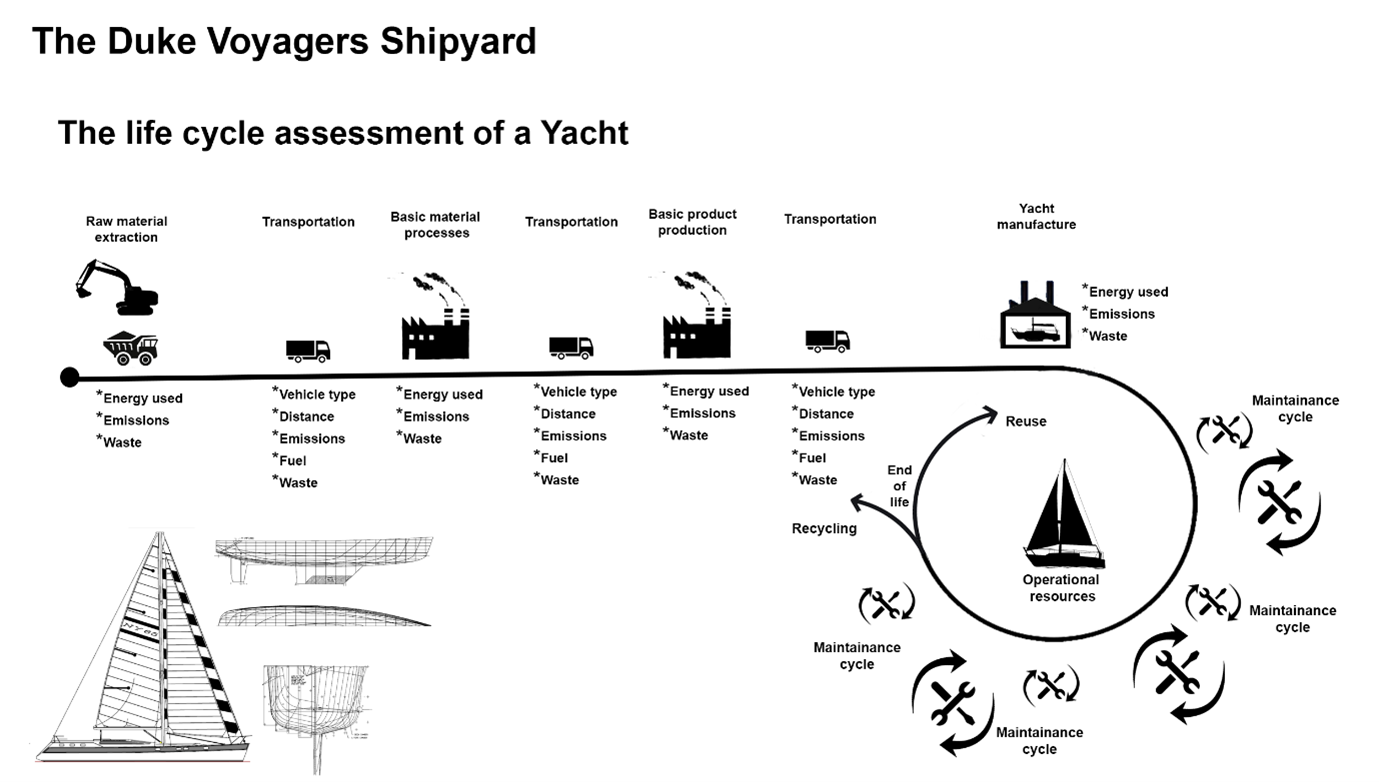

At the workshops, Tony connected with Dr Rob Barker and PhD student, Alix Overton, from the School of Physical Sciences. They carried out an initial Life Cycle Assessment which identified the key areas throughout the lifecycle of the yacht that could have an environmental impact. From there, Alix was able to propose recyclable, low-carbon alternatives to some of the more traditional materials used in the yacht-building industry. The team also helped Tony to explore sustainable energy sources for the manufacturing process and suitable site locations to minimise transportation to the launch site.

The result

As a start-up, the Duke Voyager’s Shipyard have benefitted hugely from accessing Government funding to work with the University of Kent. It has enabled them to bring chemistry expertise into the project and subsequently, explore new avenues for innovation and growth.

One example of this is the suggestion that the Shipyard use bioresin as a replacement for polyester or epoxy resins in the composite hull of the yacht. Rob and Alix initially identified a readily-available product but upon further investigation, found that the recycling process was not environmentally friendly. As an alternative, they are now exploring whether they can harness additional funding to develop an original bioresin. If successful, this material could be sold to other yacht manufacturers, creating an additional income stream for the Shipyard and transforming the industry.

Since partnering with the University of Kent, the Shipyard have been nominated for the Net Zero 50 list, hired new members of staff and identified a location to establish a shipyard. They plan to secure future funding in consortium with university partners and industry and aim to build the yacht in 2025.

Dr Rob Barker and his team have also been working with Cummins to boost sustainable behaviour in their office and WebComm to drive sustainability in the manufacturing industry. Find out more about WebComm’s project in the video below

Webcomm: driving sustainability in the manufacturing industry

About the Community Renewal Fund

The UK Community Renewal Fund was designed to provide £220 million in additional funding to help places across the UK prepare for the introduction of the UK Shared Prosperity Fund. The University of Kent and the Kent Invicta Chamber of Commerce were awarded £625k for the ‘Net Zero Pathway for Change’ Project, which included the University-led Net Zero Deep Dive Training Programme, the Innovation Intervention Vouchers, and the Student Business Innovation Challenge. The use of the vouchers were limited to priority areas of Swale, Thanet, Canterbury and Gravesham.

This funding is no longer available but our dedicated business and innovation gateway team are regularly developing new ways to support the funding of innovation projects between our academic experts and the business community. To speak to our team about the opportunities available, get in touch here.