Improving Biotherapeutic Knowledge, Skills, and Capacity Across the National and International Bioprocessing Community

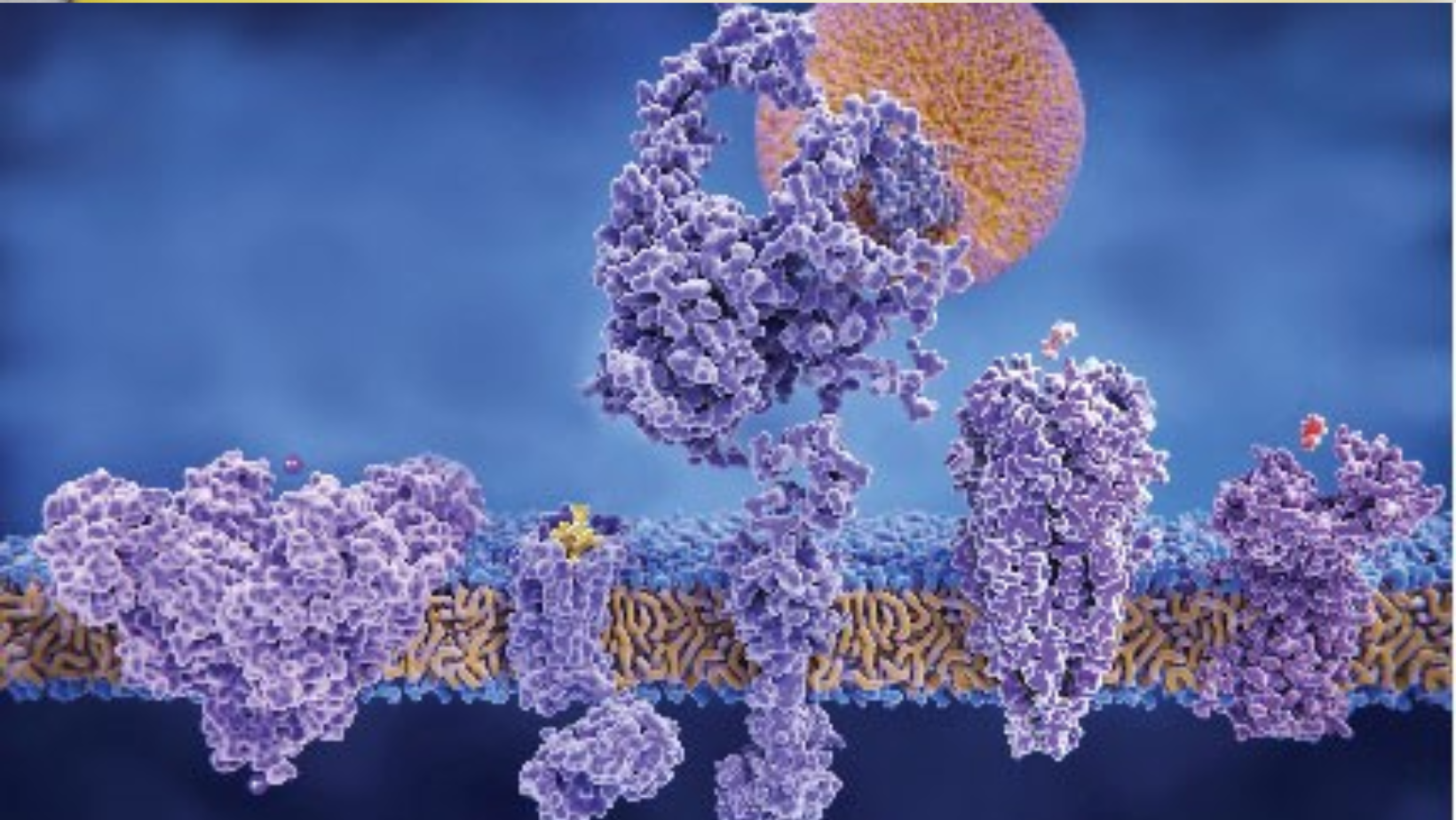

Recombinant proteins manufacturing is a highly important area in the pharmaceutical industry for producing complex therapeutics. Recombinant protein-based biotherapeutics are frontline drugs manufactured using biological means that target society’s most challenging diseases. They form the basis of a worldwide industry that in 2019 was worth >US$250 billion. A broad range of products include monoclonal antibodies, growth factors, hormones, blood factors and enzymes. Protein-based drugs, such as monoclonal antibodies are high value agents used for disease therapy or as diagnostic tools that are widely used in the health care sector. Antibodies, are extremely effective for the treatment of a number of diseases including diabetes and cancer.

Chinese hamster ovary cells are the main mammalian cell expression system currently used for the production of recombinant protein-based biotherapeutics. Ground-breaking work at University of Kent has shown that genetic engineering of Chinese hamster ovary cell lipid metabolism results in enhanced recombinant biotherapeutic protein production by manipulating the amounts of key lipids within the cells, tuning protein production and so improve yields of protein biotherapeutic drugs. This could significantly improve the production of difficult-to-make proteins so that they can be made in sufficient quantities to be tested in the clinic. This will open up opportunities to develop new protein drugs for diseases where no good treatments are currently available. This research has been part of a longstanding and successful collaboration with business organisations and is a standout example of how academia can work with industry to provide creative solutions for industrially relevant problems.

Establishing a protein production process is time and resource intensive. Development of many promising new therapies that target otherwise untreatable conditions is frequently impeded by difficulties in laboratory techniques required to manufacture appropriate protein.

Research led by Professor Mark Smales into the development of novel technologies and protocols for use in the production of biotherapeutics provided new strategies that improve manufacturing processes. The research led to patents and the advance of industrially relevant skills, know-how, and capacity-building across the national and international bioprocessing community. Specifically, the research enabled the production of higher-quality proteins in greater yields than previously possible. Furthermore, Professor Smales developed and facilitated training across the UK, India, and Thailand. This advanced the industrially relevant skills of early career researchers and helped to establish India’s and Thailand’s abilities to produce high-value recombinant biotherapeutics for their own needs.

The SARS-CoV-2 pandemic has highlighted the need for access to rapidly produced, reliable diagnostics with the required sensitivity and specificity at a cost affordable to lower and middle income as well as higher income countries. Protein-based diagnostic development and manufacture is reliant upon the availability of key protein based reagents that are critical components of these tests. Such tests may need to be manufactured in their billions a year and thus a secure and sufficient supply of authentic and low cost protein reagents is required. For example, for a simple Malaria lateral flow test, 3 different protein reagents are required in 10-500 mg quantities per million tests with an anticipated need of 400 million tests per annum. Commercially available protein reagent expression systems for production of recombinant proteins that exist have been developed largely for the expression of high-value proteins to use as drugs to treat a range of diseases and conditions. Access to such systems involves prohibitively high costs that in turn make the use of these essential reagent proteins to manufacture diagnostics in the necessary high volume problematic.

Dr. Mark Smales, Professor of Industrial Biotechnology, is applying his expertise in Recombinant protein research to address unmet need of access to recombinant protein reagents at a lower cost allowing their application into commercially viable diagnostics. His projects helped establish technologies, knowhow and systems within leading UK diagnostics companies for the rapid production of affordable, quality recombinant protein reagents, in sufficient amounts, to be viable for application into low cost rapid diagnostics for distribution in both developed and developing countries. This will secure reagent provision for development and manufacture of diagnostics and also provide the ability to generate new essential protein reagents swiftly in response to current and emerging needs at a cost that allows their application into diagnostics.

His current project relates to development of a Rapid Point of Care Diagnostic Immunoassay for Detection of Infections in Cystic Fibrosis (CF) Patients. Chronic infections are the leading cause of morbidity and mortality in cystic fibrosis patients. There is an urgent need for sensitive and reliable diagnostics of initial infection that will allow early treatment in CF patients. The work will bridge the gap between proof-of-concept studies already demonstrated and development of a prototype assay ready for clinical evaluation, advancing the technology that enables continuous monitoring and early detection of infection in CF patients, allowing early treatment and prevention of chronic infection.

Professor Smales and his group, based in the School of Biosciences have several on-going projects to further advance our understanding of biotechnological products and processes at the fundamental biological or chemical level. The School of Biosciences at the University of Kent is renowned for delivering high-quality research and training across the Bioprocessing remit. Their projects are designed to work with a variety of stakeholders to deliver research and training that help meets the current strategic need of the industrial and academic bioprocessing community.

Researchers from the School of Biosciences developed a quick and simple diagnosis method, similar to a dipstick pregnancy test, to fight a deadly sleeping sickness. The test to diagnose just requires a pin-prick blood sample and will remove the need to take complex equipment into remote areas of sub-Saharan Africa.

Researchers in the School are also working to help generate a vaccine against coronavirus, while also providing support to a key company developing urgently required antigen and antibody tests. Using the School of Biosciences expertise in recombinant protein production, synthetic biology and bioinformatics, researchers identified key antigen targets within the virus, developed and assembled constructs and will employ plug and play technology to help generate immune-responsive particles.

The team of researchers is led by Professors Mark Smales and Martin Warren and the project reflects the versatility of groups that tackle global research challenges through the provision of vaccines, biotherapeutics and nutrients in developing countries. The team works closely with colleagues at the Quadram Institute in Norwich and virologists in the University of Liverpool to move the project forward.